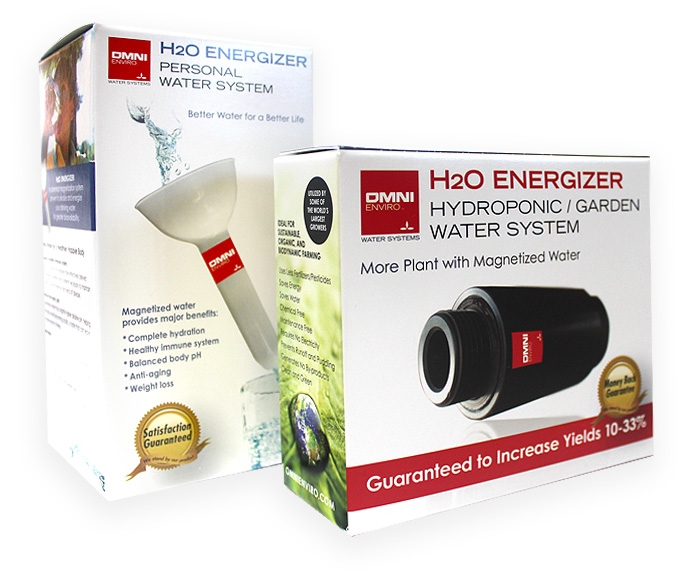

Proud to announce our new packaging has arrived for the Hydroponics/Small Garden System, and the Personal Use System!

Blog

Archive for the ‘General’ Category

New Packaging is Here!

Monday, July 26th, 2010Wisdom of the Last Farmer

Wednesday, June 30th, 2010A new find… perhaps something worth reading?

An excerpt from the Forward, which pulled me in immediately, goes like this…

“I first heard of Mas in 1994, when I was in the kitchen at Chez Panisse and a dessert leaving the pastry station caught my eye. Actually I more or less gasped in disbelief, and that’s not because the dessert was so beautiful or ornate (it was) or because I hadn’t seen a dessert like it before (I hadn’t). I gasped because it was so crazy. It was a single peach on a dessert plate, no sprig of mint, no swish of raspberry sauce. It was Peach, unadorned.”

…”It was the best peach of my life; but I have to qualify that because like most Americans born in the last fifty years, I didn’t know what a peach should taste like. Breeders in the ’70s and ’80s created low-acid, high-sugar peaches that can be picked when they’re still hard, making them suitable for withstanding the rigors of cross-country travel. So we got drunk on sugar, and created taste memories that are more Mrs. Butterworth than Mother Nature. We fell for the wrong woman, and we’re still paying for it.

But my greatest memory from that night is the reaction those peaches got from older diners. Waiters reported several tables saying the same thing: “I hadn’t had a peach like that since I was a child!” The diners tore apart the peaches with their hands, talking happily about summer afternoons in their grandmother’s backyard, lazy mornings in the hammock, the smell of a late August evening.

They were incredible peaches, no doubt. But more than that—as if a peach needs to be more than that—they did that night what I suspect Mas is most thrilled about.

They got people to consider the connection between good food, which is of course food grown in the right way and picked at the most perfect moment, and the memorable moments of life.”

- Dan Barber, Executive Chef and co-owner of Blue Hill Farm

The Wisdom of the Last Farmer

By: David Mas Masumoto

Trade Shows !!!

Friday, January 15th, 2010Please come and visit with us at any of these trade shows… We look forward to meeting you!

You can find the links on the About Us page.

Jan 14, 2010

Suisun Valley Show, Fairfield, CA – 7:30am

(Thurs)

Jan 20-23, 2010

Eco-Farm Conference, Pacific Grove, CA

(Wed – Sat)

Jan 27-28, 2010

Unified Wine & Grape Symposium, Sacramento, CA

(Wed – Thurs) BOOTH 239

Feb 6-7, 2010

CCOF Education Conference ‘Healthy Soils, Healthy Food’, Chico, CA

(Sat – Sun)

Feb 9-11, 2010

World Ag Expo, Tulare, CA

(Tues – Thurs) BOOTH 2210

Feb 15-17, 2010

Pistachio Industry Conference, Santa Barbara, CA

(Mon – Wed) BOOTH 2

Feb 28 – Mar 2, 2010

California Small Farm Conference, San Diego, CA

(Thurs – Sat)

Mar 10-12, 2010

Pistachio Conference, Monterey, CA

(Wed – Fri)

NON-CHEMICAL WATER TREATMENT

Friday, February 6th, 2009The Facts…

Non-chemical technologies for scale and hardness control are not new. The scientific community has published hundreds of articles on this principle since the 1960s. The fundamental theory is very simple:

Pass water through a magnetic field and it changes the water.

This has been studied now for decades by academics and industry alike. Below is an example of some of the publications found in our research of this technology and how they explain the theory, use and application of these devices.

U.S. Department of Energy, Office of Energy Management, Federal Technology Alert, January 1998:

“The operating principles for the electrostatic units are much different. Instead of causing the dissolved ions to come together and form non-adherent scale, a surface charge is imposed on the ions so that they repel instead of attract each other. Thus the two ions (positive and negative, or cations and anions, respectively) of a kind needed to form scale are never able to come close enough together to initiate the scale-forming reaction. The end result for a user is the same with either technology; scale formation on heat exchange surfaces is greatly reduced or eliminated.”

“These technologies can be used as a replacement for most water-softening equipment. Specifically, chemical softening (lime or lime-soda softening), ion exchange, and reverse osmosis (RO), when used for the control of hardness, can be replaced by the non-chemical water conditioning technology. This would include applications both to cooling water treatment and boiler water treatment, in once-through and re-circulating systems”

Sandia National Laboratories, Operated for the U.S. Dept. of Energy by Sandia Corporation. Surface tension testing conducted November, 2004.

“two tap water samples with excessive hardness showed reductions in surface tension relative to unconditioned tap water of from 10%-20%, with an average of 14% and 17% respectively for the two samples. These results are based on a series of five separate tests for each set of water samples. In all cases tested, the conditioned water always showed a lower surface tension than the unconditioned water.”

“A reduction in water surface tension will improve soils wetting, especially in clayey soils, and improves soils moisture in irrigation applications (Israelsen, 1962). A reduction in surface tension in water will change wetting characteristics, increase wetting surfaces, and change the distribution of solutes on wetted surfaces (Weber, 1972).”

Parsons, et. al., “Magnetic Treatment of Calcium Carbonate Scale – Effect of pH Control,” Water Research, Volume 31, No. 2, pp. 339-342, 1997.

“scale formed on the heat exchanger for the experiments were reduced by 48% after magnetic treatment… The pH profile of experiment MGC indicates a direct effect of magnetic treatment on the solution pH. During the experiment, the pH of the magnetically treated system falls by 0.5 pH units from pH 8-7.5, then towards the end of the experiment slowly returns to its original value of pH 8.0. This variation has been attributed to slow degassing of the solution.”

Li, J. et al., “Quantitative study of the effect of electromagnetic field on scale deposition on nanofiltration membranes via UTDR.” Water Research (2007).

“Various chemical or physical methods have been employed in order to prevent filter membrane inorganic fouling (Baker et al, 1997, Hasson et al, 1997: Likikanen et al2002: Litsitsin et al, 2005) As the use of scaling inhibitors changes the water composition; they have to be avoided for drinking water distribution. (Gaberielli et al, 2001). Therefore, physical methods are proposed because they do not change the properties of water. In particular, magnetic water treatments, due to its advantages such as low cost, simple operation, and no harm to the environment, have attracted much attention (Baker and Judd,1996: Gehr et al, 1995; Nevedrov and Ushakove, 2003; Parsons et al, 1997; Wang et al,1997).

“Donaldson and Grimes (1998) discovered that the ration of calcite to aragonite precipitated from a saturated solution was influenced by magnetic treatment. Higashitani et al, (1993) confirmed that a magnetically treated solution favored aragonite growth”.

“Al-Qahtani (1996) found that in a seawater RO unit, the permeate salt concentrations of the magnetically treated solution were lower than that of untreated ones, and the magnetic field enhanced both conductivity and pH value of the solution. The results also showed that the rejection of RO membrane increased in the presence of magnetic field. Vedavyasan (201) reported that the fouling rate of the RO membrane is considerably reduced and the overall performance of the RO plant was improved when induced with magnetic field. The results showed large savings in energy by 18%, process downtime costs by 30% and cleaning by 33%.”

Omni Water Technology has thoroughly investigated the science behind magnetic water treatment. We have diagnosed the reasons for past inconsistencies, and identified the correct technology to maximize performance of Non-Chemical Water Treatment. The Water Conditioner is a cost effective, environmentally friendly, simple solution for all industries using substantial amounts of water in their processes.

Less Water, Better Yields, Lower Costs

Wednesday, January 14th, 2009Our non-chemical water technology improves water quality, reduces total dissolved solids, and provides a return on your investment in both crop yields and cost savings within the first season.

USE LESS WATER - because both soil & plants will absorb water better, resulting in less pooling, less run-off & less evapo-transpiration..

GET BETTER YIELDS - (Defined as “better volume, better taste & longer shelf life”) because more nutrients are dissolved into the water and then absorbed into the plant.

INCUR LOWER COSTS – because less water is used (and less electricity is needed to pump the lower viscosity water); less fertilizer is used; harvests come earlier; & irrigation equipment maintenance costs are lower (from less scaling).

Magnetic Technologies in plant growing

Friday, January 9th, 2009Nowadays, many written scientific works of biologists and biophysics describe the effect of magnetic fields on plants. Based on these works, OmniEnviro came up with a method of magneto-hydro dynamical activization of natural waters and devices used for this method. This method is an essential part in the whole complex of using magnetic fields in agriculture. It includes physical- chemical changes of natural water parameters, resulting in improvement of filtration properties and in an increase of dissolving properties of water. These changes result in an increased ability of soil to get rid of salts and results in a better assimilation of nutrients and fertilizer in plants during the vegetation period.

It is known that plants and trees need mineral salts and microelements from the soil to function and photosynthesize properly. However, plants do not use the majority of nutrients that are in soil. While watering plants with normal water, only a small amount of nutritional elements dissolves in the soil and becomes available to the plants. Further consumption of these nutrients from the soil is very rare when plants start to grow and a larger amount of nutrients is required, the deficit of microelements results in low numbers of crop. The deficit of microelements/nutrients in the soil is the main reason for a decreased growth rate and low crop. That is the reason to why magnetic water should be used for irrigation.

In addition, when the plant is watered using hard and non- magnetized water, white coating is formed on the surface of the soil: that is calcium bicarbonate and carbonate. Some of calcium bicarbonate is washed away by water penetrating soil and depositing on the roots of plants. The plant, then, starts to suffocate because of these depositions and in order to continue to feed, forms additional roots. This process results in a decrease of normal growth in plants.

However, plants that are irrigated using water that is treated by OmniEnviro, easily take in mineral salts from the soil and no sediment is formed on the soil surface. Also if mineral and organic fertilizers are used, they dissolve better which results in their need for use the decrease by 50% and at the same time, plants still continue to develop without any extra effort. This results in an increased crop production and in an increased quality of agricultural products.

In short, the economic advantage of using magnetic water for irrigating the crops looks like this:

Advantages

Vegetation period decreases by 15-20 days, therefore the crops ripen 15-20 days earlier than normal.

Crop production increases from 15-20% to 100%, and in some cases, even more.

Plant disease rates drastically decrease.

Taste of agricultural products improves.

Approximately 30% less water is used for irrigation.

Therefore 30% less energy is used in water pipes.

Sea water (salty water) can be used for watering (from 6-8 thousand PPM inclusive) and for some cultures, very salty water can be used (from 15 thousand inclusive).

By magnetizing seeds before sowing and by irrigating them with magnetic water, the need for crop material decreases by min. 30%.

Average of 30% decrease in fertilizer consumption.

Active soil desalination takes place, increasing crop production year after year.

Expenses

Expenses that occur during the installment of magnetic systems for 2.5 acres of land come up to approximately 500$US. In addition, our magnetic devices do not need technical maintenance and do not require electrical energy. Life of our devices is min. 10 years. If we divide 500$US by 10 years, our expenses will be 50 $US/year. Compare advantages with expenses and draw your own conclusions!

Below, we included reports of various organizations, which use our technology and our devices. These experiments were carried out in different parts of the world, in different climates and on different soil; that gives us the right to say that using magnetic technologies has no limits and limitations when it comes to various conditions and situations.

As we see, the mentioned above results show that using magnetic water can only be an advantage.

Conditions of experiments

All of the experiments were carried out using the same method. That is a land area was chosen and divided into two equal parts. One part was used as a control and was watered using normal water. The second half had magnetic devices installed. After that, same kinds of seeds were planted in both areas at the same time.

The following changes were recorded:

In plants:

Speed of crops’ standing.

Percentage of crops standing.

Development of root system.

Difference in green mass.

Development of first flowers.

Development of first fruits.

Quantity of fruits.

Time of collecting the harvest.

Difference in quantity and quality of harvest.

In soil:

Amount of salts at different depth of the soil (0-1.5m) before the irrigation process.

Amount of salt in soil while watering with normal and magnetic waters.

Density of water that has flown through the soil.

Speed of filtration in the beginning and at the end.

Washing away of salts while irrigating soil with water.

Washing out of various anions from the soil.